The EcoStack: From Waste to Fuel

The EcoStack

The EcoStack is a revolutionary new chimney that will recycle carbon dioxide into synthetic fuels and oxygen. This will help keep global warming under control.

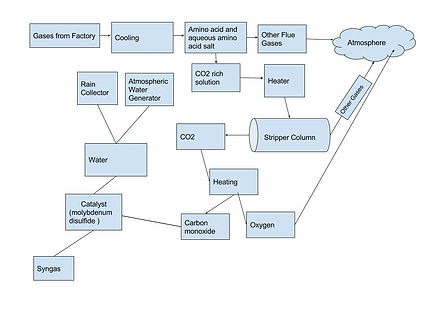

To the right you can see a basic diagram of how our EcoStack works. There are two main stages to this process: carbon dioxide capture and fuel conversion.

Stage 1: Carbon dioxide capture

During this stage, carbon dioxide is separated from other flue gases. As flue gases flow up the chimney, they are cooled into liquids. This liquid is pumped up into an absorption column, where an amino acid and aqueous amino acid salt liquid absorbs all the CO2. The CO2-rich liquid is then pumped up into a stripper column. In the stripper column, CO2 is extracted from the liquid using a vapor stream. This CO2 continues to the second stage, where it is converted to fuel.

Stage 2: Fuel Conversion

After the CO2 is separated from the other gases, it needs to be converted to fuel. Since CO2 is fairly nonreactive, it is first converted to carbon monoxide (CO). To do this, the CO2 is heated so that it has enough energy to break a bond between a carbon and oxygen atom to form CO and O. The extra oxygen atom will be bonded to create an oxygen molecule and released into the environment. Since the fuel product also requires hydrogen, the EcoStack collects water from rainwater and uses and atmospheric water generator to draw water from moist air. The water is split into hydrogen and oxygen using an electrical current (electrolysis). The hydrogen and carbon monoxide is bonded using chemical reactions that are accelerated by the molybdenum disulfide catalyst to create synthetic fuel, or syngas.